Oddly as it may seem the refrigeration system is one of the most efficient forms of heating – think Heat Pump.

Most businesses that operate refrigeration equipment are only concerned with the cooling aspect of the system, whether its cooling food & drink or people.

A refrigeration system with an energy consumption of 1kW will dissipate 4kW of unwanted waste heat to atmosphere.

This waste heat is from a combination of sources including the heat being extracted from the product being cooled and the refrigeration compressor itself.

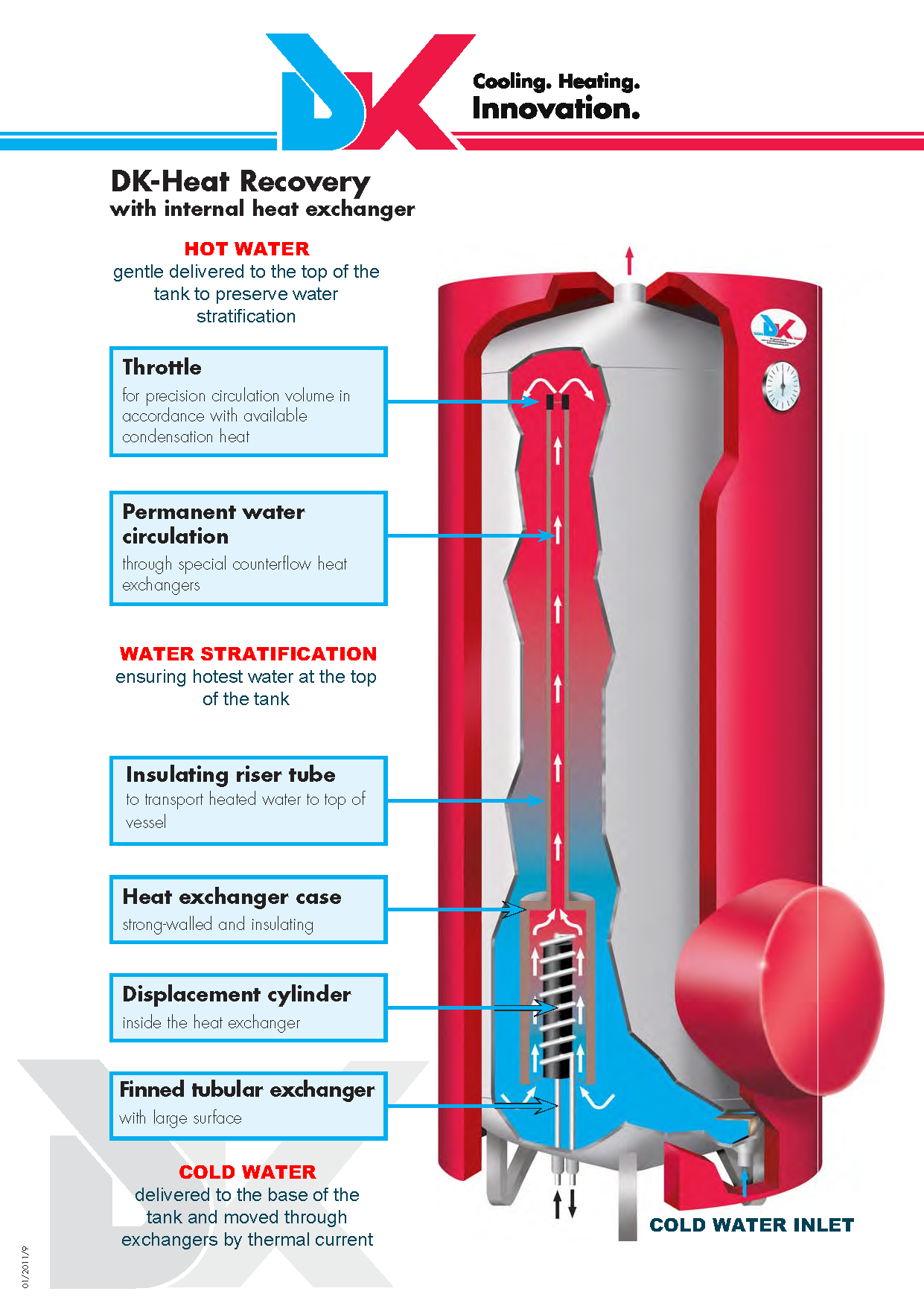

Placing a heat exchanger between the compressor and the point of the traditional waste heat rejection process can recover much of the heat previously destined for the bin.

If we go back to the 4kW of unwanted heat for a moment and consider this figure in terms of hot water production using this valuable free energy source – we can now view this as the ability to produce 80 litres of hot water per hour.

The typical temperature of the refrigerant discharge gas (the heat source) is around 90C, that’s hot. Especially when you consider that your hot shower in the morning is normally set at 38C.

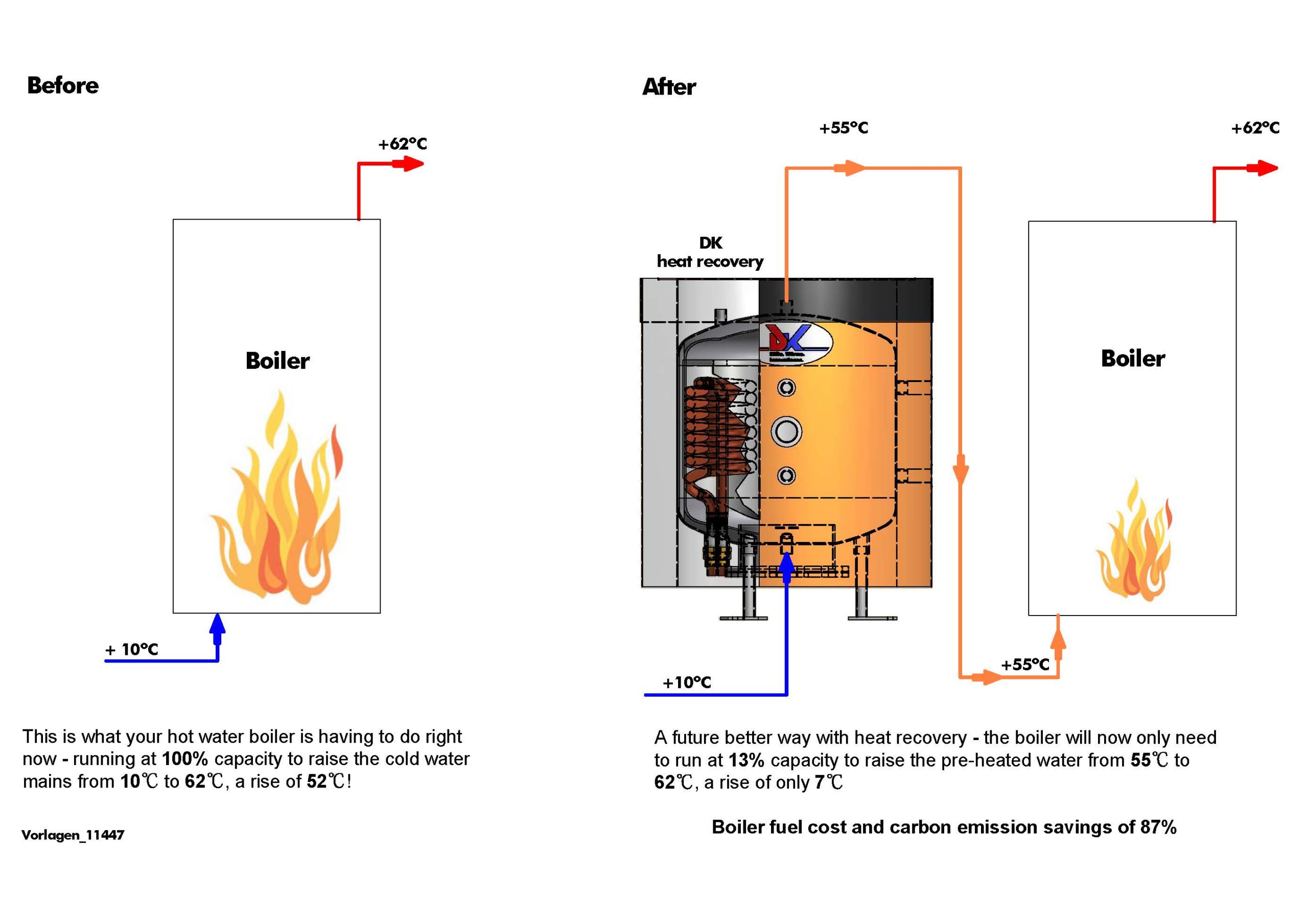

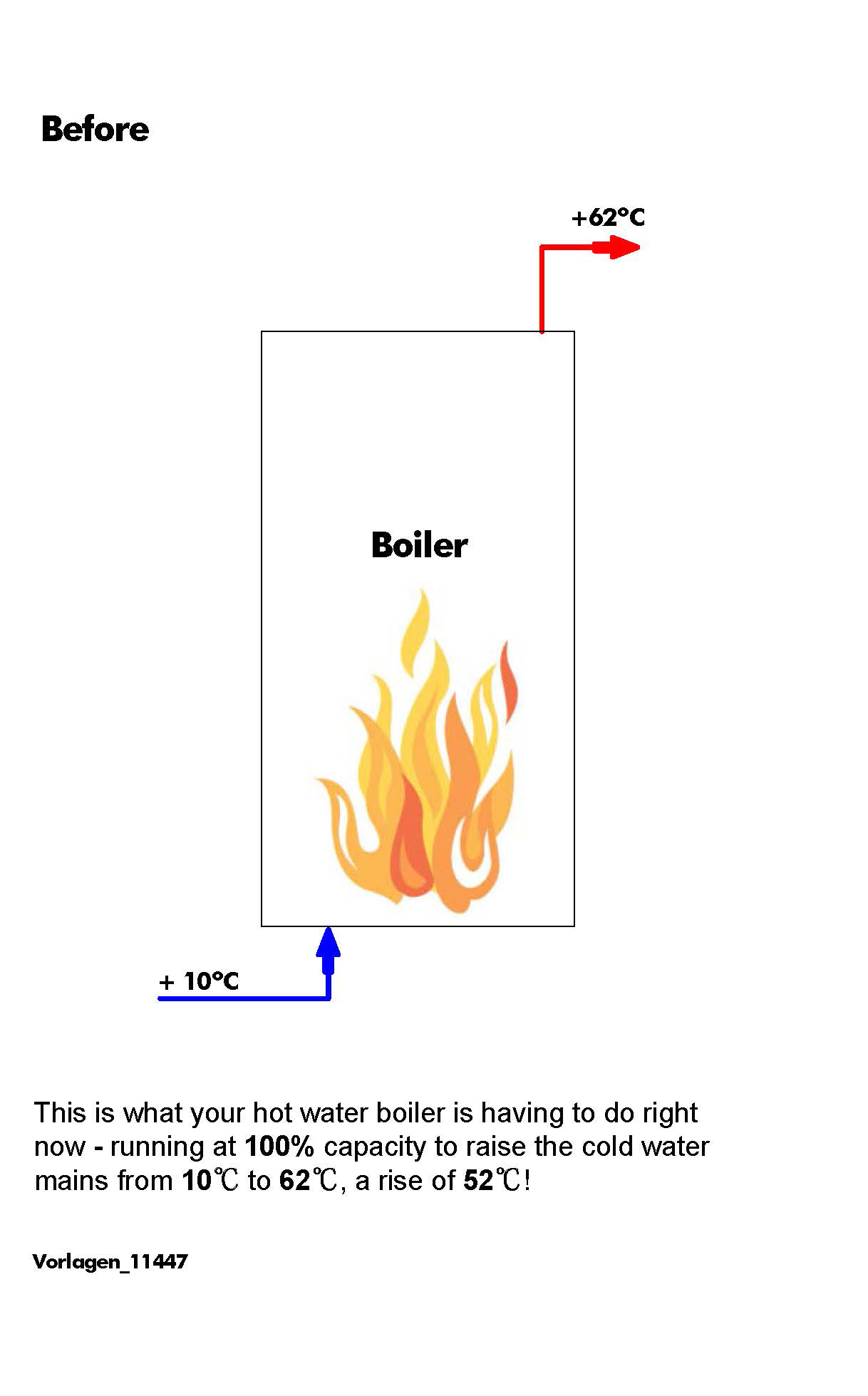

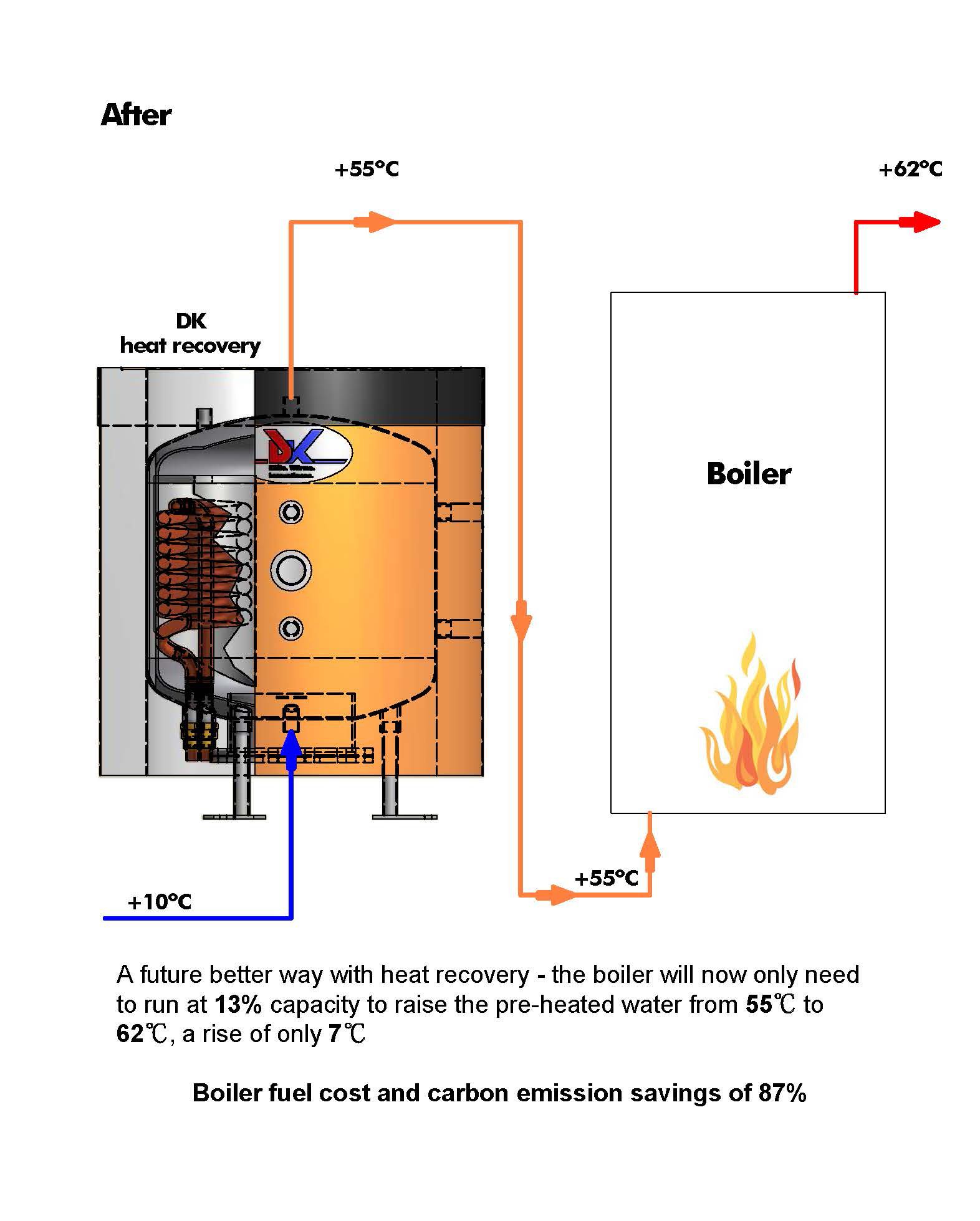

The effect of installing a heat exchanger will be noticeable from the word go, as the illustration below will show, in terms of hot water boiler fuel consumption and C02 reductions.

Imagine not having to pay for your hot water!

How does it work?

In simple terms the hot refrigeration gas that is normally sent to the condenser for cooling is diverted to pass through a DK heat recovery system where it heats the water instead of being wasted. No noise or moving parts; just quietly getting on with the job of saving money and carbon emissions.